Laboratory Facilities

The Department is well equipped with state-of-the art laboratories and infrastructural facilities in all the thrust areas. Students get a wide exposure and practical hands on training in the sophisticated equipment during their lab sessions.

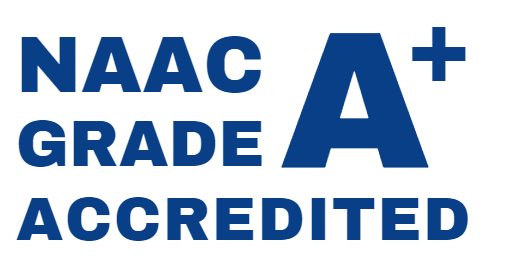

CAD Laboratory

CAD Lab has equipped with more than 30 Computer Systems with high end latest Configuration hardware. The software available include AutoCAD 2015, SolidWorks 2019, ANSYS R21, MATLAB etc,.

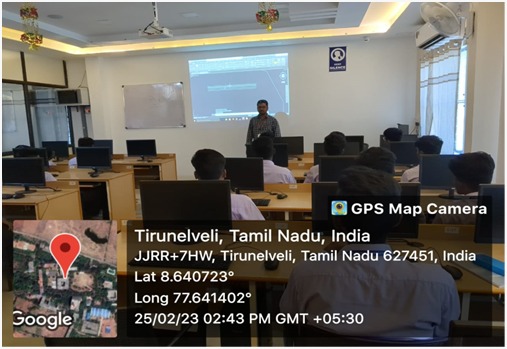

Workshop Practice Laboratory

Mechanical Engineering Workshop is a place of where students acquire knowledge on the operation of various process involved in manufacturing and production. The workshop practice course makes students competent in handling practical work in engineering environment. Workshop is a place where students acquire knowledge on the operation of various processes involved in manufacturing and production. The Workshop Practice course makes students competent in handling practical work in engineering environment.

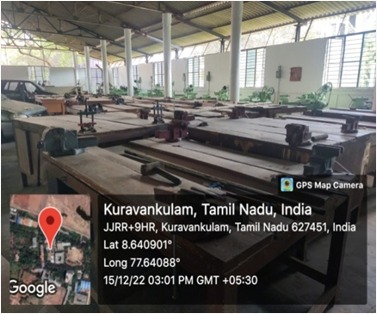

Mechatronics & Robotics Laboratory

The laboratory deals with fundamental and current issues of mechatronic components in various machines. Especially in the field of sensor and control technology there are extensive training and investigation possibilities. Robotics, mechatronics, and advanced manufacturing and automated fabrication processes are the rapidly developing, interdisciplinary areas of engineering research dealing with the design and realisation of intelligent products, systems and processes.

Fluid Mechanics Laboratory

The Fluid Mechanics laboratory is designed to examine the properties of fluids and to conduct experiments involving both incompressible and compressible flow. Experimental setups such as flow through a tube, flow over a flat plate, wind tunnel, smoke tunnel and viscometer are made available to the students. The lab experiments utilize U-tube manometer and digital manometer, a hot-wire anemometer system and data acquisition.

Metrology & Measurements Laboratory

Calibration and use of linear measuring instruments – Vernier caliper, micrometer, Vernier height gauge, depth micrometer, bore gauge, telescopic gauge, Comparators. Measurement of angles using bevel protractor, sine bar, autocollimator, precision level. The purpose of this laboratory is; to familiarize students with laboratory measuring devices, to study the measurements methods, to learn proper measuring techniques through simple measurements of mass, length, and time, and to learn to express the results of calculations so as to correctly reflect the effects of measurement uncertainty.

Dynamics & Metrology Laboratory

Calibration and use of linear measuring instruments – Vernier caliper, micrometer, Vernier height gauge, depth micrometer, bore gauge, telescopic gauge, Comparators. Measurement of angles using bevel protractor, sine bar, autocollimator, precision level. The science of mechanical measurements has its roots in physics. It is an independent domain of knowledge dealing with the measurement of various physical quantities such as pressure, temperature, force, and flow.

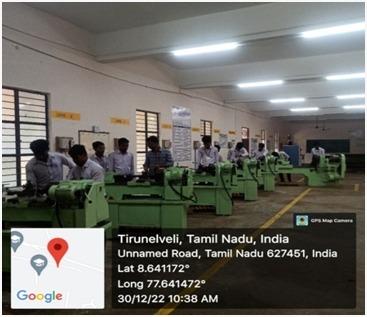

Manufacturing Technology Laboratory

This lab focuses on developing the students’ skills towards metal cutting activities, through introducing different metal cutting machines and processes. It also develops the skill of the students towards process planning, machine and process selection. As a general definition, manufacturing technology describes the application of tools and processes — developed through scientific, industrial and engineering advances — to improve the efficiency, quality and productivity of operations.

Strength of Materials Laboratory

Strength of material laboratory provides the basic knowledge of strength of materials and the students can perform different tests on variety of materials. Experiments are performed to measure the properties of materials such as impact strength, tensile strength, compressive strength, hardness. The objective of the strength of materials lab is to demonstrate the basic principles in the area of strength and mechanics of materials and structural analysis to the undergraduate students through a series of experiments.

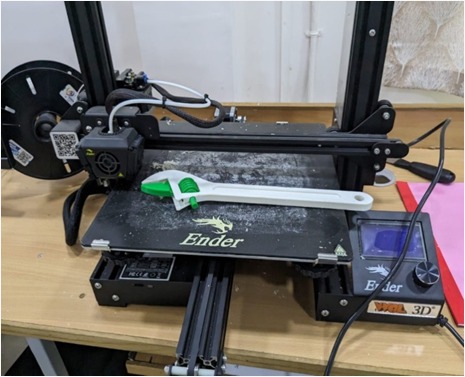

3D Printing Laboratory

With a 3D printer lab, users can prototype and produce custom parts, models, and products for a wide range of applications, including engineering, product development, art, and education. The lab is aimed at giving exposure and enhancing the knowledge and skills of engineers involved in the operation use of 3D Scanners, 3D Printers, CAD packages and for those who want to provide training to others in this area.

Composite Materials Fabrication & Testing Laboratory

We test for properties such as toughness, hardness, resistance to cracking, strength, cure, flame resistance, heat resistance, temperature limit, impact strength, viscoelasticity, ductility, tensile stress, compressive stress and shear stress. Composite fabrication processes typically involve some form of molding, to shape the resin and reinforcement. A mold tool is required to give the unformed resin/fiber combination its shape prior to and during cure.

Solar Thermal Laboratory

Solar thermal energy (STE) is a form of energy and a technology for harnessing solar energy to generate thermal energy for use in industry, and in the residential and commercial sectors. Roof-mounted close-coupled thermosiphon solar water heater. Solar water heating systems, or solar thermal systems, use energy from the sun to warm water for storage in a hot water cylinder or thermal store.

Student Project Laboratory